A banjo bolt is a crucial component in automotive and hydraulic systems. It is a fastener that is part of a banjo fitting, which is commonly used for fluid transfer in various applications.

The bolt is typically hollow with a hole on the side, allowing fluid to pass through. It is designed to fit through the center of the banjo fitting, which also has a hole in it. The fitting has flat surfaces that seal with a washer, usually a crush washer, allowing fluid to flow around the bolt.

Banjo bolts are commonly found in brake systems, oil transfer systems, and fuel fittings in motorcycles. They offer a clever engineering solution for flexible line installation and fluid transfer.

Key Takeaways:

- A banjo bolt is a fastener used in automotive and hydraulic systems for fluid transfer.

- It is hollow with a hole on the side to allow fluid to pass through.

- Banjo bolts are commonly used in brake systems, oil transfer systems, and fuel fittings in motorcycles.

- They provide a clever engineering solution for flexible line installation and efficient fluid transfer.

- Understanding the role and applications of banjo bolts is crucial for professionals working with fluid systems.

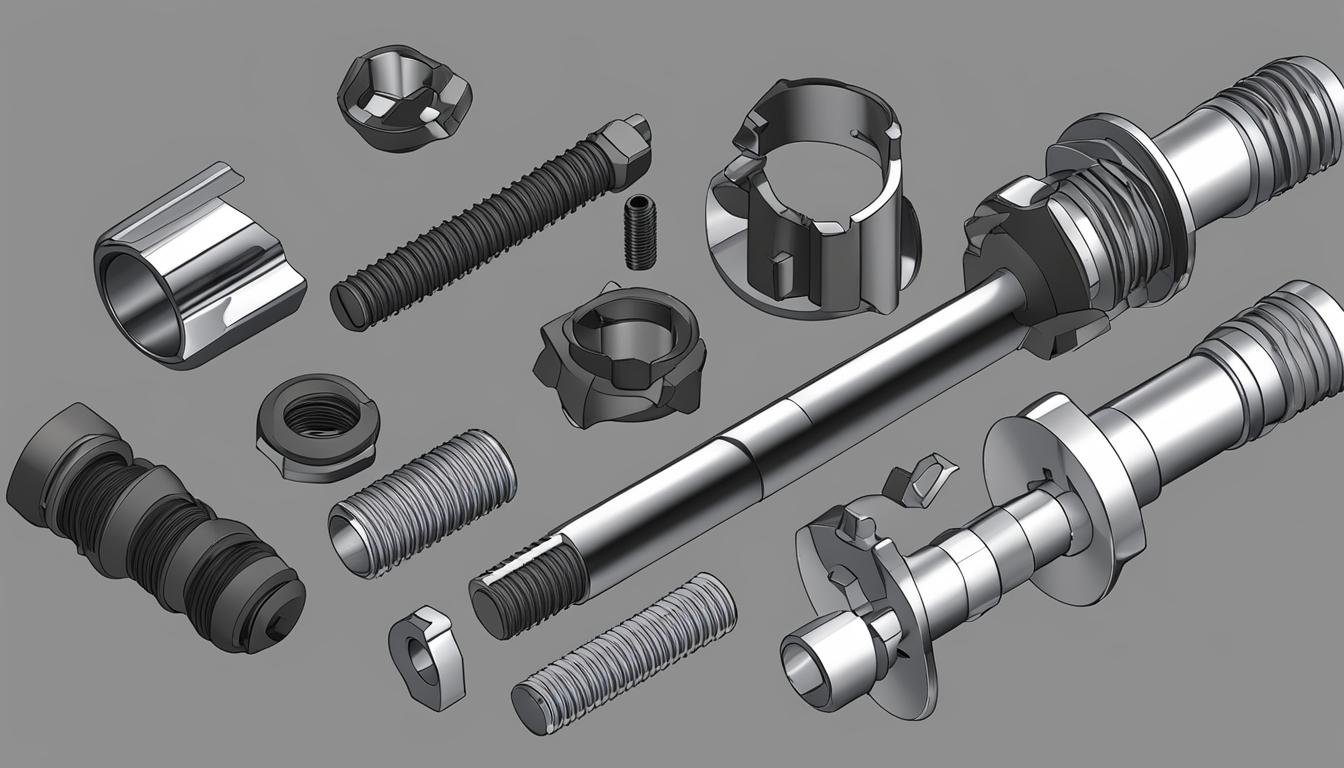

The Anatomy of a Banjo Bolt: Components and Design

A banjo bolt consists of three main components: the head, the body, and the washer. The head is the visible part of the bolt, while the body is the middle section that may or may not have threads. The washer is located underneath the head and provides additional protection against damage and corrosion.

The bolt is specifically designed to fit onto a tube or pipe and connect to other components such as valves or hoses. Its unique shape, resembling a banjo with a large circular section connected to a thin pipe, gives it its name. Banjo bolts have the advantage of not requiring rotation during installation, reducing the risk of damage.

When used in banjo fittings, the bolts allow fluid to pass through their hollow center and into the other part of the fitting. The flat surfaces of the banjo fitting, sealed with a washer, enable fluid to flow around the bolt without requiring perfect alignment of the holes.

The Anatomy of a Banjo Bolt: Components and Design

Applications of Banjo Bolts in Automotive and Hydraulic Systems

Banjo bolts play a vital role in various automotive and hydraulic systems, offering versatile applications for fluid transfer. One of the most common uses of banjo bolts is in brake systems. These bolts connect brake lines and hoses, ensuring the efficient transmission of hydraulic pressure to enable proper braking functionality.

Another significant application of banjo bolts is in oil transfer systems. They are commonly utilized to connect components such as coolers to facilitate the smooth flow of oil. These bolts provide a reliable and secure connection, ensuring the proper and efficient transfer of oil within the system.

In addition to brake and oil transfer systems, banjo bolts are also commonly found in fuel fittings. In motorcycles, banjo bolts are used to connect fuel lines to gas tanks, enabling the seamless flow of fuel. This application highlights the versatility of banjo bolts in various fluid transfer scenarios.

Advantages of Banjo Bolts over Traditional Fittings

When it comes to fluid transfer in automotive and hydraulic systems, banjo bolts have a distinct advantage over traditional threaded fittings. One of the key advantages is that banjo fittings do not require rotation during installation, significantly reducing the risk of twisting and damaging hoses. This makes them not only easier to install but also provides a more secure and reliable connection.

Another advantage of banjo bolts is their flexibility in positioning. Unlike threaded fittings that require rotational adjustment, banjo bolts allow for easy adjustment of the pipe exit direction without the need for rotation. This is particularly beneficial in situations where space is limited, as it provides more flexibility in the installation process.

Furthermore, banjo bolts are particularly well-suited for high-pressure applications. Their unique design, with a hollow center and sealed flat surfaces, ensures efficient fluid flow and minimizes the risk of leakage. This makes them a preferred choice in systems where a secure and reliable fluid transfer is crucial.

The Benefits at a Glance

- No rotation required during installation, reducing the risk of hose damage

- Easy adjustment of the pipe exit direction without rotation

- Ideal for high-pressure applications

- Secure and reliable fluid transfer

With their numerous advantages, banjo bolts continue to be a popular choice in automotive and hydraulic systems. Their ability to provide secure connections, flexibility in positioning, and efficient fluid transfer make them a valuable component in various fluid transfer applications.

Conclusion

In conclusion, banjo bolts are essential components in automotive and hydraulic systems, providing efficient fluid transfer and enabling flexible line installation. Their unique design and advantages make them a popular choice in various applications, including brake systems and oil transfer systems. By understanding the anatomy, function, and applications of banjo bolts, professionals can ensure reliable and secure fluid transfer in their respective industries.

With their clever engineering and reliability, banjo bolts have proven to be a valuable solution for fluid transfer for many years. Their name, derived from the banjo-like shape of the fitting, reflects the ingenuity behind their invention. From their hollow center to the flat surfaces that seal with a washer, banjo bolts offer a practical and effective means of fluid flow control.

Whether it’s connecting brake lines, oil transfer systems, or fuel fittings, banjo bolts provide a versatile and efficient solution. Their advantages over traditional threaded fittings, such as easy installation without the need for rotation and flexibility in positioning, make them a preferred choice in fluid systems with limited space. Furthermore, banjo bolts excel in high-pressure applications, ensuring a secure and reliable fluid transfer process.

In summary, banjo bolts are an integral part of fluid systems, allowing for efficient fluid transfer and providing an effective solution for flexible line installation. By harnessing the benefits of banjo bolts and understanding their role in automotive and hydraulic systems, professionals can optimize their fluid transfer processes and ensure smooth operations.

FAQ

What is a banjo bolt?

A banjo bolt is a fastener that is part of a banjo fitting, commonly used for fluid transfer in automotive and hydraulic systems.

How does a banjo bolt work?

A banjo bolt is hollow with a hole on the side, allowing fluid to pass through. It fits through the center of the banjo fitting, which also has a hole. The flat surfaces of the fitting seal with a washer, enabling fluid to flow around the bolt.

Where are banjo bolts commonly used?

Banjo bolts are commonly found in brake systems, oil transfer systems, and fuel fittings in motorcycles. They are also used in power steering fluid systems, variable valve timing systems, and turbocharger oil feeds, among other applications.

What are the advantages of banjo bolts over traditional threaded fittings?

Banjo bolts do not require rotation during installation, reducing the risk of hose twisting and damage. They also allow for easy adjustment of the pipe exit direction without rotation, making them ideal for situations with limited space.

What is the function of banjo bolts in fluid systems?

Banjo bolts control the flow and transfer of pressurized fluid in fluid systems. They allow fluid to pass through their hollow center and into the banjo fitting, enabling efficient fluid transfer.

How long have banjo bolts been used?

Banjo bolts have been used in various applications for many years. Their unique design and engineering have stood the test of time and continue to be utilized in modern automotive and hydraulic systems.